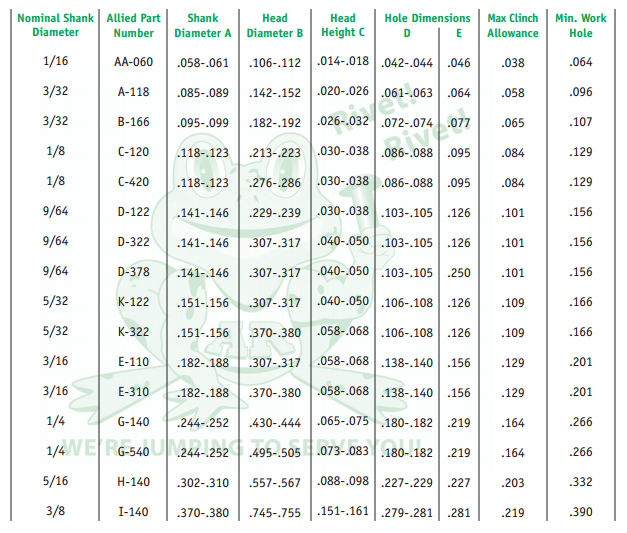

Remember that insufficient rivet length will not allow proper formation of the secondary head at the back of the work. You must select a rivet with a grip range that includes the work thickness required. This determines the required "grip" of the rivet you select. Measure the total thickness of the materials to be joined. POP ® brand rivets are not certified for structural aerospace applications and such use is not recommended. Then refer to the "Shear" and "Tensile" in the Rivet Selection Guide on the product and select a POP ® brand rivet that provides the values required. These are functions of total joint strength, fastener spacing, rivet body material, and rivet diameter. Joint strengthįirst determine the single-joint tensile and shear values required for the application. The load applied to a fastener along its length. The load applied to a fastener along the joint interface. The recommended thickness range over which the body length will consistently provide a proper setting in a hole of the specified diameter. (Best practice is to follow the hole size recommendations provided).Īvoid burrs in and around the holes. It may also cause bulging or separation of the members by allowing the rivet to expand between them instead of only on the blind side. Too large a hole will reduce the shear and tensile strengths. Too small a hole will, of course, make rivet insertion difficult. Hole size can be important in blind riveting. Use the data in our rivet size chart below to help make your choice and prepare the rivet hole.This illustration provides a graphic representation of the POP ® blind rivet selection factors described below. Choose the closest standard rivet size that is equal to or larger than those dimensions. The rivet shank diameter should be equal 3 times the thickest sheet being joined.

Pop rivet sizes mm plus#

The rivet shank length should be equal to the thickness of both layers you are joining plus 1.5 times the diameter of the rivet’s stem.

Pop rivet sizes mm how to#

How to Choose Rivet Size – Rivet Diameter and Length Calculation Metric: Rivet size diameters and lengths are measured in millimeters.Rivet lengths can be measured out to half sizes (i.e. For example, a “dash 3 dash 4″ means a rivet size of 3/32″ diameter and 4/16” length. These values are expressed as “dash numbers”. Imperial: Rivet diameters are measured in 1/32″ increments and the lengths are measured in 1/16″ increments.We provide a rivet size chart (below) to give you the data you need to prepare a hole for all popular rivet sizes. The area that deforms is the rivet shank. The rivet hole must be prepared based on the rivet’s requirements. One of the most important tasks when planning to use rivets is hole preparation. They’re also often called Pop Rivets because that’s the sound they make as the wire is broken off the back of the rivet. These are called blind rivets because they can be installed even when we can’t see the other side of the sheets being fastened.

In fastening applications, rivets have many advantages over more standard nut and bolts:īy Heedless – Own work, CC BY-SA 4.0, Wikimedia Rivets are typically used in aircraft construction, boat building, aluminum, and steel construction (such as heavy iron work). Rivets are typically used to fashion sheet materials together like sheets of metals, plastics, woods (including wood beams), and even textiles or leather.

This article provides you with a rivet sizing chart and an easy guide to how to use the information to choose the proper rivet size for your application.

0 kommentar(er)

0 kommentar(er)